Our Processes

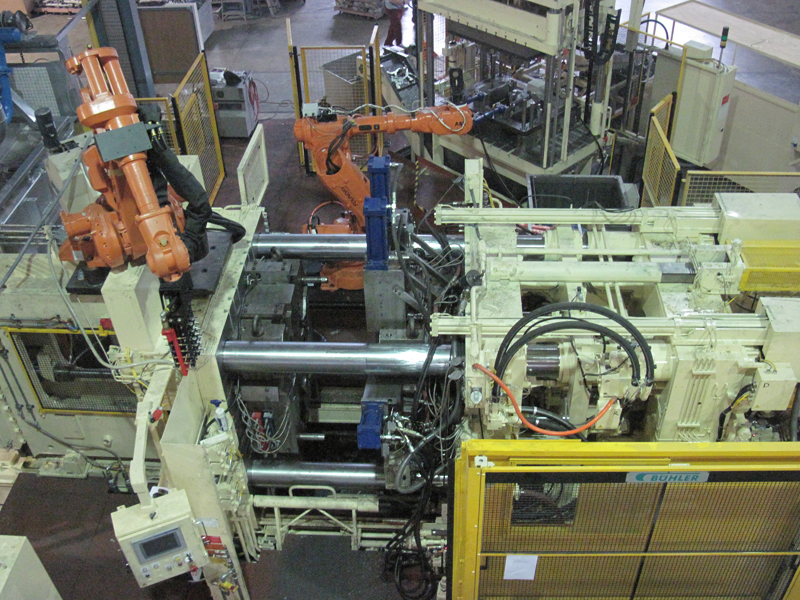

High Pressure Die Casting

CastAlum has eleven fully-automated high pressure diecasting cells in the range of 1,000 – 2,000 tonne locking-force. Each cell has its own integral bulk-melting tower furnace to ensure that the correct quantity and quality of metal is always on hand.

Recyclable material from the trim press is fed directly back into the furnace, eliminating any possibility of contamination between differing grades of aluminium. This process is highly suited to complex thin-walled castings.

Squeeze Casting

In addition, CastAlum has three fully automated cells for the manufacture of indirect squeeze castings in aluminium.

The process is ideally suited to the manufacturing of high-integrity castings with a requirement of thick wall sections and mechanical properties approaching those of a forged component.

Machining

In 2009, CastAlum built a dedicated machine shop within the existing Welshpool facility to provide a full-service to new and existing customers alike. The machining area benefits from a clean climate-controlled air supply and is supported by dedicated CMM, Pressure Testing and Gauging areas.