High Pressure

Die Casting

Automated, industry leading excellence

CastAlum has been high pressure die casting in the heart of Wales for over twenty years, so it’s fair to say we know a lot about the process!

About High Pressure Die Casting

A history of HPDC

While high pressure die casting (HPDC) has been around for several decades now, in its infancy it was considered an inferior process to its main competitor: gravity die casting. Some of the original problems with HPDC were:

- Expensive to set up

- More suited to long runs and large quantities

- Higher porosity and generally lower quality

For several years parts produced by the HPDC process were understood to be cheaper, but of inferior quality. To further emphasis this, HPDC utilized the LM24, considered a low-level material in terms of both quality and price.

Refining the die casting process

As die casting machine manufacturers such as Buhler Prince made their equipment more robust and predictable, the level of performance and quality of the parts began to improve. These advances included:

- Control mechanisms on shot speed, clamping, etc.

- The ability of a machine to automatically shut down a process

- Quality control from parts per minute to zero defect and then to single part rejection

The necessity to produce parts right first time has resulted in an industry-leading production process. Through the constant refinement of an already mature method, CastAlum has achieved levels of excellence that would have scarcely been thought possible back when the company was founded at the turn of the century.

The future of HPDC

Even with all these recent improvements, technical progress continues to be made. Nowhere is this more apparent than in our provision of parts to the expanding electric vehicle (EV) market. As a visionary within the industry, CastAlum is always striving to find new levels of performance and engineering distinction through a range of possibilities converted into successes, including:

- Innovation in engineering design and enhancements to in-process controls

- Light weighting whilst providing yet more complex geometries with improved integrity and strength.

- Unparalleled tooling durability with innovative additive manufacturing

Armed with over twenty years of experience and ever-increasing skillset, we’re looking forward to providing the continuous improvement and competitive benefits of high pressure die casting to our customers for the next twenty years too!

A history of HPDC

While high pressure die casting (HPDC) has been around for several decades now, in its infancy it was considered an inferior process to its main competitor: gravity die casting. Some of the original problems with HPDC were:

- Expensive to set up

- More suited to long runs and large quantities

- Higher porosity and generally lower quality

For several years parts produced by the HPDC process were understood to be cheaper, but of inferior quality. To further emphasis this, HPDC utilized the LM24, considered a low-level material in terms of both quality and price.

Refining the die casting process

As die casting machine manufacturers such as Buhler Prince made their equipment more robust and predictable, the level of performance and quality of the parts began to improve. These advances included:

- Control mechanisms on shot speed, clamping, etc.

- The ability of a machine to automatically shut down a process

- Quality control from parts per minute to zero defect and then to single part rejection

The necessity to produce parts right first time has resulted in an industry-leading production process. Through the constant refinement of an already mature method, CastAlum has achieved levels of excellence that would have scarcely been thought possible back when the company was founded at the turn of the century.

The future of HPDC

Even with all these recent improvements, technical progress continues to be made. Nowhere is this more apparent than in our provision of parts to the expanding electric vehicle (EV) market. As a visionary within the industry, CastAlum is always striving to find new levels of performance and engineering distinction through a range of possibilities converted into successes, including:

- Innovation in engineering design and enhancements to in-process controls

- Light weighting whilst providing yet more complex geometries with improved integrity and strength.

- Unparalleled tooling durability with innovative additive manufacturing

Armed with over twenty years of experience and ever-increasing skillset, we’re looking forward to providing the continuous improvement and competitive benefits of high pressure die casting to our customers for the next twenty years too!

Our Die Casting Process

Contact us about high pressure die casting here!

You can also email info@castalum.com or call +44 (0) 1938 557 557

Learn more about high pressure die casting

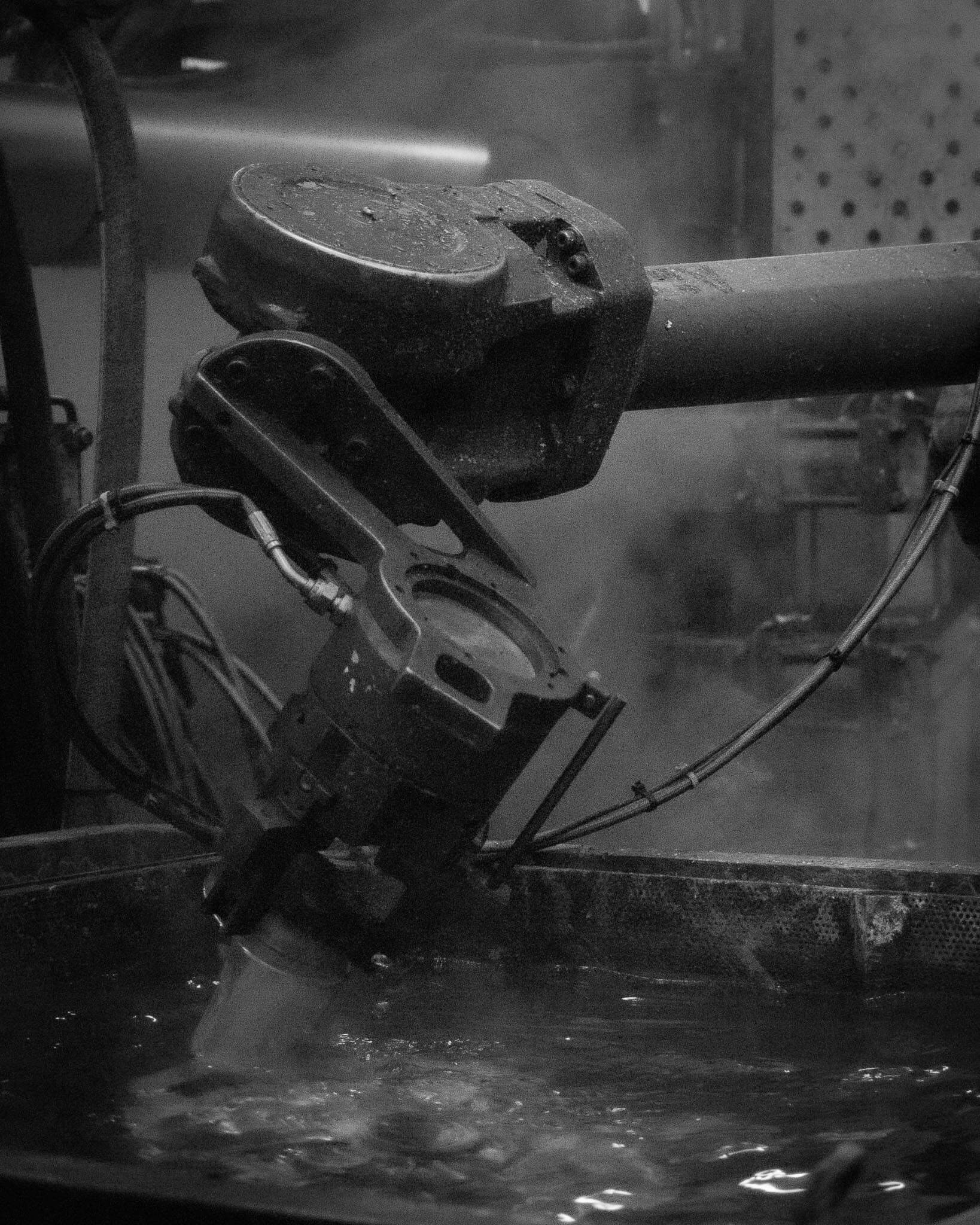

Die Casting Quench Tanks

In die casting, managing heat effectively is a crucial part of the production process. An often-overlooked part of our fully automated cell is the quench tank. Quench tanks are used immediately after a component has been cast. Our extract robots take the part from the die, and then cool them in a quench tank, before taking them over to the trimming tool.

Toolmaking in Die Casting

At CastAlum, our toolmakers are tasked with ensuring that our dies are in good working order for our die casting operations. Read on to learn about our toolroom department and the work they do to keep our die cast machines producing high quality aluminium components.

Conscientious Casting

At CastAlum, as well as striving for excellence in our manufacturing processes, we are equally committed to environment stewardship. This is reflected in our ongoing efforts towards sustainable manufacturing. Since our site was created in 2000, we have completed many site-wide and process-specific initiatives aimed at reducing our energy footprint.

X-ray in Die Casting

By using high-resolution X-ray imaging, we can quickly and efficiently identify and rectify defects and inconsistencies in our aluminium castings. This assessment can be done in real-time as parts are being made, which streamlines our production process while improving the overall quality of our products.

Shotblasting in Die Casting

One of our favourite processes here at CastAlum is our shotblasting capability. This is a process we’ve continued to invest in over the years, including the addition of a new machine from Rosler in 2022.