Die Casting Robotic Automation

If you have been following along with our employee interview series, you’ll have noticed that one of the first elements of our die casting process that impresses our employees is the sheer amount of automation present on each of the cells. Our die casting cells can have as many as four robots working to automate the entire cycle.

The last robot in the die casting process has multiple responsibilities. It removes the trimmed casting from the trim press and will deliver it to the operator ready for deburring and packing. Finally, it will return to the trim press to perform a blow off cycle. This helps to clear any debris from the press area ready for the next trimming cycle.

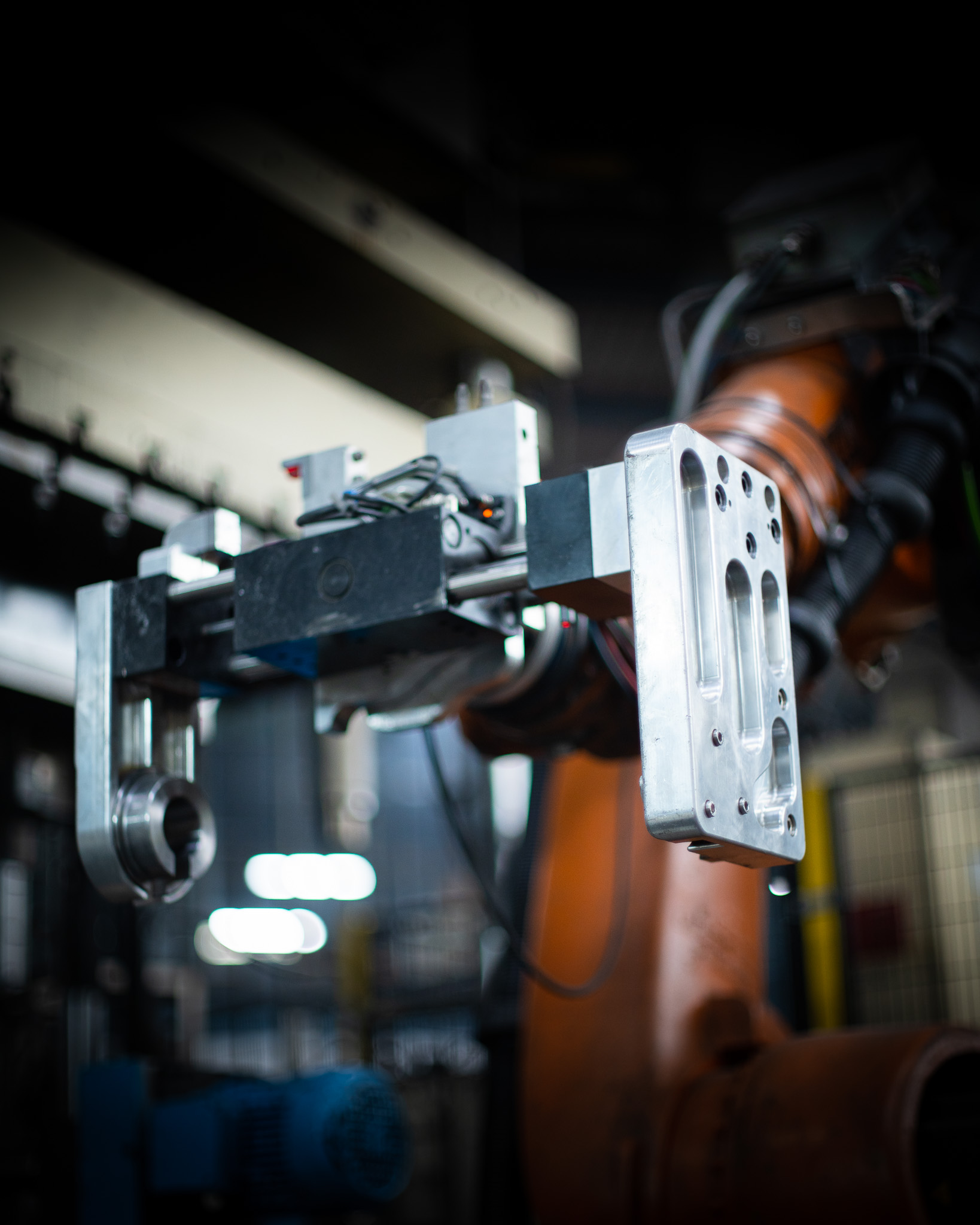

The gripper you see in the header image here is a CastAlum design and build, which was customised from an off the shelf two jaw parallel Destaco gripper, and it is mounted on a KR30 Kuka trim extract robot.

This particular gripper also performs the functioning of a loose insert as well as the casting! It separates the casting and the insert so that the insert can be re-used for the next cycle. This is another of CastAlum’s innovative solutions, and we’ll be covering it in more detail in a future newsletter.

Bringing our tooling in-house.

Historically, we outsourced the gripping solutions on our robots to external companies. But over the years we have invested in both the expertise of our engineering personnel and the equipment available to them. This means that we can now buy in a standard gripping unit and build a bespoke system around it.

This approach allows for much greater flexibility and control of the precise requirements for each of the varying products that we now manufacture. In addition to the gripping unit itself, we are also now able to design and machine all of the plates and brackets in house as well.

As die casting parts have become more complex over the years, and especially with the recognition of the light-weighting possibilities that aluminium castings provide for the electric vehicle market, the ability to make adjustments and continuously deliver improvements is one the core competencies that mark as out as the supplier of choice for our customers.

Remember to follow us on LinkedIn to learn more about our technological expertise and engineering solutions!